HOW MUCH DOES MACHINING COST?

Much Depends On Your Specific Needs

One question we’re asked every day at Distinctive Manufacturing is “here’s my CAD drawing….how much would you charge to machine my part”? Let’s talk about that!

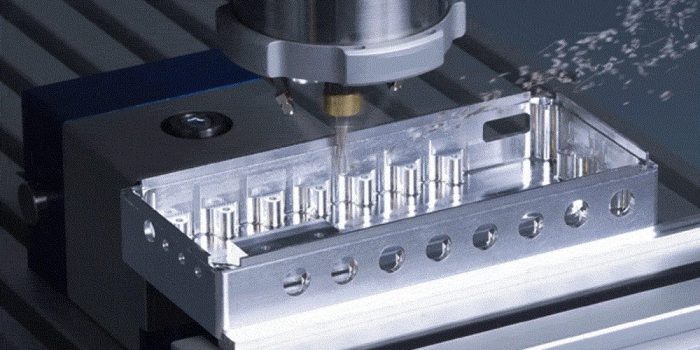

CNC MACHINING COST

One thing is for sure. As a precision machine shop, we’re not selling an off-the-shelf product with specific fixed costs. Two machined parts can look exactly the same, yet one cost significantly more than the other. Why is that? From material selection, your tolerance requirements, quantities as well as many other variables, there are many factors that will directly impact how much your machining project will cost.

The great news is at Distinctive MFG, we’re experts at guiding machining projects to successful outcomes. We’ve found that by asking the right questions up front, we can not only ensure your quality requirements are met, but also your overall experience in working with us as your machining partner.

So let’s talk specifically about a few of the common factors that affect the cost of machining services. It’s important to ask the right questions before taking on a new machining project. Here are a few questions we’ll typically ask:

WHAT ARE YOUR MATERIAL REQUIREMENTS?

First, your material selection/requirements will have a direct impact on the cost of your machining project. Of course some raw materials are more expensive than others, but the material itself can affect the machining process and overall cost. We call this machinability.

Some materials are just harder to machine than others. The machinability of the material can affect both labor and tooling costs. Take aluminum machining, or machining with 303 stainless steel vs titanium machining, as an example.

Parts machined out of titanium are going to have different factors to consider than machining parts out of 303 stainless steel or aluminum. When it comes to material selection, we’re well-versed on matching the proper materials with the intended use of machined parts.

HOW MaNY MACHINED PARTS DO YOU NEED?

Next, how many parts are you needing to have machined? Obviously, larger quantities of machined parts will have a higher overall cost than a single machined part. However, the cost per part will go down as the quantity increases. Next…

HOW SOON DO YOU NEED YOUR MACHINED PARTS?

We pride ourselves on being able to meet deadlines that other machine shops can’t, but turnaround time does play a part in the cost of our CNC machining services. Special planning needs to be on our end to accommodate rush jobs so if you need your machined parts in days rather than weeks, the pricing will be affected.

DO YOU HAVE A CAD DRAWING?

If you already have a drawing of your part to be machined, great. If not, and you’re needing a bit of assistance with the part design that’s fine too. Parts design assistance or prototyping would definitely have an impact on the cost of machining.

HOW COMPLEX IS YOUR MACHINED PART?

Machined parts with a great deal of complexity will cost more than machined parts that are less complex. They require more processes which will affect the cost of machining.

During the part design phase it’s easy to unknowingly design parts that are expensive to machine. We’re well-educated in the manufacturing process and often make design suggestions that can simplify the part without affecting functionality or reliability.

WHAT ARE YOUR TOLERANCE REQUIREMENTS?

Machined part tolerances will also affect pricing. One example why: Parts requiring extreme tolerances require more frequent tool changes which add to the overall machining cost.

Do you need a variance of +/- .001 across all of your part dimensions, or can we scale that back to specific critical dimensions and save you some money? These are questions your machining provider should be asking.

DO YOU HAVE SECONDARY MACHINING PROCESS NEEDS?

For even tighter controls over the shape and surface finish of your machined parts, we’ll often utilize secondary machining processes including painting, plating, precision grinding, annealing, anodizing, powder coating, etc. If this is something that you require for your machined parts the cost of machining services would be impacted.

MACHINED PARTS INSPECTION?

Parts inspection doesn’t always come to the top of mind when asking about the price of machining. However, it does matter. Do you have a specific frequency of inspection requirement for your machined parts? For example, if you require 100% of machined parts to be inspected, that would cost more than a machining project with no inspection requirement or had a small AQL (accepted quality limit).

Again, this is where machining and manufacturing experience comes into play. We’ll typically balance the frequency of inspection by the risk. Our objective here is to inspect no more machined parts than needed to ensure that your critical tolerances are maintained.

DO YOU NEED YOUR MACHINED PARTS SHIPPED?

Do you need your machined parts shipped? If so, where, and how soon do you need them? Shipping parts to Hawaii is going to cost more than shipping machined parts to Florida, for example. Using our trusted network of shippers, we’ll work with you to deliver your precision machined parts when you need them.

READY TO REQUEST CNC MACHINING PRICING?

Whether you’re an engineer with a strong technical understanding of CNC machining, or have zero experience in working with machine shops, we’re here to guide you through the process from start to finish. Reach out to Distinctive Manufacturing Group today and let’s have a conversation or learn more about our machining services!

Need pricing on a metal fabrication project, CNC machining project, prototyping services or 3D printing?